Metal materials are popular used in many industries, such as construction, medical, electronic materials and other fields have a wide range of applications. The most common including stainless steel, aluminum alloy, powder metallurgy and other metal materials are widely made into a variety of metal accessories, after precision machining which used in 3C, tableware, medical equipment, construction and other equipment and facilities.

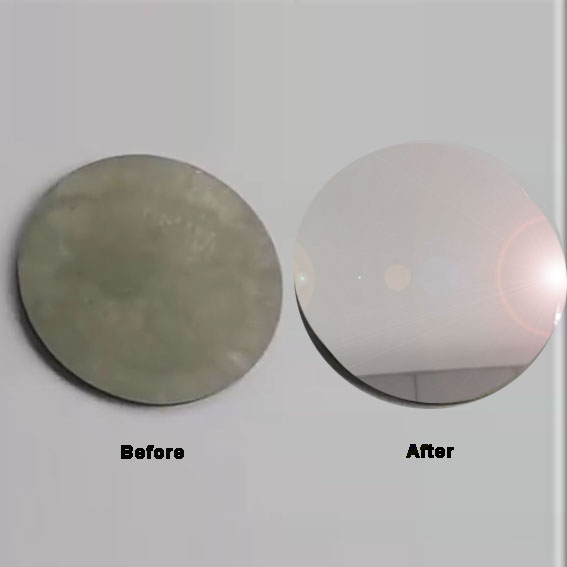

For equipment manufacturers in 3C or other industries, the most common requirements for precision processing is mirror-like finish.That is, metal polishing is required to be smooth and shiny like a mirror.

In order to achieve the mirror-like effect, the most common solution is through chemical mechanical polishing. In chemical mechanical polishing, polishing slurry or polishing wax should be used with polishing pad and polishing machine. There is a problem in metal polishing, which is the conflict between polishing efficiency and the final mirror-like finish.

In order to solve this problem, there are strict requirements for the polishing slurry and wax in their abrasive particle size , and high requirements for the the width of the particle size distribution of the abrasive. Including the primary particle size and the secondary particle size, both of them neither too small (because there will be no cutting force) not too large (because it will not meet the requirements of mirror surface finish after polishing). After hundreds of experiments , we found that sub-micron particle size is more suitable.

That means, there are high requirements for dispersion technology in producing polishing slurry and wax, we should control the primary and secondary particle size of the polishing slurry and wax for metal mirror like polish.